Aqua-Sac Flood Sack - Inflatable Flood Sand Bag for Flood Defense - Self-Inflating Flood Defence System (Quantity of 1 is 5 Flood Sacks)

- Buy 5 for £25.56 £21.30 each and save 8%

- Buy 20 for £23.70 £19.75 each and save 15%

- Buy 100 for £21.90 £18.25 each and save 22%

- Buy 200 for £20.46 £17.05 each and save 27%

- Buy 500 for £19.86 £16.55 each and save 29%

AQUA-SAC® flood defence bags can be swiftly deployed to prevent damage caused by flood waters. Supplied in packs of 5 bags

Pack of 5 Aqua-Sac® Flood Bags - Self-Inflating Flood Defense Solution - Hydro-sack Sandbags for Flooding

Key Features & Equipment Benefits:

AQUA-SAC® S.O.S. Bags are used for flood control in a similar way to traditional sandbags. Inflated S.O.S. Bags contain water absorbed in SAP. Compared to traditional sandbags, they are lighter and easier to handle. A number of S.O.S. Bags can be used to form a dam to divert a flow of water.

Each AQUA-SAC® comprises of a heavy duty jute sack with a cotton liner containing a super absorbent polymer which weighs only 440g; this means that a pack of 25 bags weighs less than one sandbag!

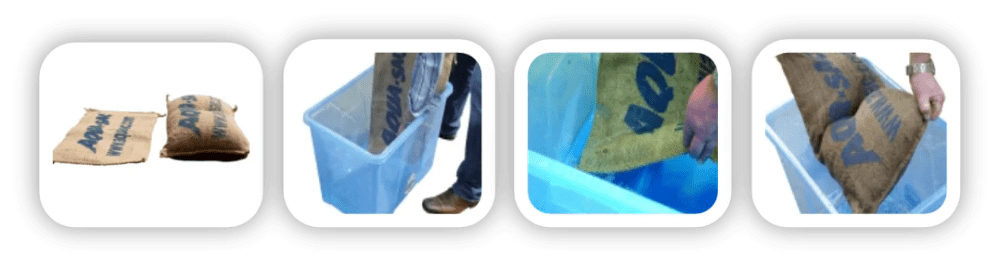

The bag is simply submerged in water for approximately 5 minutes after which time 13 litres of water will have been absorbed creating an inflated sandbag .The fully inflated bag weighs 13kg thus conforming to UK health and safety legislation for a single lift (Max. 15kg) and measures 10.5cm high, 54cm long and 31cm wide.

Direction of Use:

After soaking in water for 3 -5 minutes, the S.O.S. Bag self-inflates to over 30 times its original size. Uninflated bags are so lightweight and compact that 1,000 can be stored on one standard pallet compared to only 25 traditional sandbags. After inflation, the AQUA-SAC® S.O.S. Bag can be used in the construction of flood defences such as dams.

Environmental Impact:

The bags have little impact on the environment as both the jute sack and the cotton liner are biodegradable. The super absorbent polymer is benign with no toxic effects ensuring that the bags can be safely disposed of in landfill or by incineration. Alternatively the super absorbent polymer can be used as a hydrating medium by adding it directly to soil.

Shelf Life:

AQUA-SAC® are contained in sealed packs with a shelf life in excess of 5 years.

TECHNICAL DATA

AQUA– SAC® Bag Specifications

Dimensions:

o Dry bag (length x width) 60 cm X 37 cm

o After inflation (length x width x height) 54 cm X 31 X 10.5 cm

Weight:

o Dry bag, as supplied 0.4 kg

o After inflation in fresh water 13 kg

Environmental Considerations

The AQUA-SAC® S.O.S. Bag contains three components: a jute sack, a cotton inner bag, and a superabsorbent polymer (SAP). None of these components is considered toxic to the environment.

Over 60% of the dry weight of the S.O.S. Bag comprises jute and cotton. These natural fibres are easily biodegradable.

SAP (cross-linked sodium polyacrylate) comprises about 33% of the dry weight of the S.O.S. Bag. This material is similar to that used in baby nappies and adult incontinence pads; it is also added to soils and composts to improve moisture retention. SAP is non-toxic to aquatic or terrestrial organisms at predicted exposure levels, and is relatively inert in aerobic and anaerobic conditions, with practically no degradation.

It is effectively immobile in landfills and soil systems, with over 90% retention; the mobile fraction shows some biodegradability.

SAP is easy to eliminate in water-treatment plants due to its insolubility. Therefore, incidental down-the-drain disposal of small quantities of SAP will not affect the performance of wastewater treatment systems.

Elimination (persistence and degradability) information is available on request.

Health and Safety

The components of this product are not considered hazardous, as no particular hazards are known.

AQUA-SAC® S.O.S. Bags contain sodium polyacrylate, a superabsorbent polymer (SAP), the same absorbent material used in disposable nappies.

Disposal

SAP is a non-hazardous waste suitable for disposal in an approved solid waste landfill or incineration plant, in accordance with local regulations.

Therefore, unused (dry) and used (wet) S.O.S. Bags can be sent to landfill or incineration.

Another possibility for disposal of limited numbers of AQUA-SAC® S.O.S. Bags is so -called greening, whereby bags are buried under a tree during planting to provide a water reservoir.

If greening is impractical, bags may be cut open to remove the SAP, which can be dug into soil to improve moisture retention.

General Fire Hazards

No recognised fire hazards are associated with the AQUA-SAC® S.O.S. Bag or SAP.

Hazardous Combustion Products - None known

Extinguishing Media - Dry chemical, foam, carbon dioxide, and water fog. Extremely slippery conditions are created if SAP is spilled out of the bags and comes in contact with water.

Fire Fighting Instructions - Firefighters should wear full protective clothing including self-contained breathing apparatus.

Avoid inhaling dust during clean up (see Inhalation below).

Any small residual amount of SAP may be flushed with water into the drain for normal biological wastewater treatment.

Seepage - the outer surface of the bags can be slippery when wet, and the ground under an inflated bag will sometimes be slippery. To limit the damage, lay a few S.O.S. Bags flat on the floor around the inside of doorways and other openings to avoid the surface becoming wet.

Bag removal and Clean up after flood: once the bags have been removed from site it is essential to power-jet to remove any residue that may be left behind before walking on the wet surface.

Emergency Overview

Sodium polyacrylate (SAP) is chemically stable under normal and anticipated storage and handling conditions.

Under normal circumstances, users of AQUASAC® S.O.S. Bags should not come into contact with SAP. However, SAP may leak or spill from a broken S.O.S. Bag, or it may be released from the bag as a result of tampering.

SAP dust may escape from the inner bag due to rough handling of large numbers of S.O.S. Bags, during unpacking and stacking.

Although SAP is not regulated as a hazardous material, the respirable dust is a potential respiratory tract irritant.

The European Disposables and Non-Wovens Association (EDANA) recommends a workplace limit of 0.05 mg/m³ for respirable dust of SAP (particle size under 10 microns) based on the NOEL (No Observed Effect Level) of a 2 year inhalation study.

Sodium polyacrylate is a white, granular, odourless polymer that yields a gel-like material with the addition of water. It is insoluble in water and causes extremely slippery conditions when wet.

Potential Health Effects

Eyes - SAP dust may cause burning, drying, itching, etc. resulting in reddening of the eyes.

First Aid – If SAP dust is formed, wear protective goggles. If SAP dust gets in the eyes, immediately flush with plenty of water. Remove any particles remaining under the eyelids. Get medical attention if irritation persists.

Skin - Exposure to SAP dust, may aggravate existing skin conditions due to drying effect.

First Aid - Remove SAP dust from skin using soap and water. Take off contaminated clothing.

Ingestion - Tests have shown that SAP is nontoxic if ingested. First Aid - As in any instance of non-food consumption, seek medical attention immediately if there are any ill effects.

Inhalation - Inhaling SAP dust may cause respiratory tract and lung irritation and may aggravate existing respiratory conditions. If SAP dust exceeds the 0.05 mg/m³ limit, wear an appropriate respirator, and ensure sufficient workplace ventilation.

Contact Us

Need any help? Get in touch with an expert via the contact form below.