Heavy-Duty 'Military' Shelter

The Heavy-Duty Military Shelter from I.C. Brindle—engineered for rapid deployment with a rugged, inflatable design perfect for creating a modular command post. Featuring a durable 630g PVC sealed waterproof outer cover, this shelter offers exceptional reliability in harsh environments.

The shelter includes flame-retardant materials throughout, covering the frame, outer cover, and inner liner. With integrated power and lighting solutions, it meets the needs of military and industrial operations.

The modular design can accommodate a range of configurations, including large central tents with smaller annexes, offering flexible solutions for your operational requirements.

Features include large vehicle flaps for anchoring, versatile window options, connectable doors, and conveniently located inflation/deflation valves.

The heavy-duty fast inflation shelter is a military-grade 'turnkey' solution, fully equipped and 'ready made' with service ports, carry bags, repair kits, and heavy-duty stakes.

CAD drawings are provided for customisation, and onsite training is available. This shelter is ideal for versatile and efficient deployment in critical situations.

Organisation branding is available upon request.

Request your free quote

Answer the following questions below so we can give you a quote on your selected item(s)

Key Features & Equipment Benefits:

- Constructed with a 630gr PVC, fire-retardant, and sealed waterproof outer cover, it ensures exceptional durability.

- Internally lined for effective insulation

- Modular Design allows for a wide range of configurations

- All materials, including the frame, outside cover, and inside liner, are fire-retardant.

- Windows on each side which have 3 usable options, a fly mesh for ventilation.

- Clear PVC Cover to allow light and a Cover for complete privacy.

- The ends of the shelters have full sized doors which are connectable so you could put two or more shelters together to make a large welfare area if required.

- Inflation/Deflation Valves for inflation with an electric pump or BA Cylinder and Hose.

- An Over Pressure Valve which makes sure you cannot over inflate the shelter .

- A Pressure Sensor Valve that allows and regulation pump to be used, this is particularly useful if your using the shelters for long periods of time as the pump will detect any drop in pressure and top up accordingly.

- 'D' Rings sewn into the internal beams to allow accessories (such as lighting) to be secured to.

- Service port at each end.

- Carry Valise/Bag.

- Full Repair Kit.

- Heavy Duty Stakes.

Used For:

- Our shelters, crafted from the latest fire-resistant, waterproof, and water-repellent materials, are designed to provide versatile solutions for various needs. Such as:

- Military Personnel Housing / Command Centres

- Long-Term Operations in Remote Locations

- Humanitarian Relief Efforts

- Heavy-Duty Field Hospitals

- Storage for Sensitive Equipment and Supplies

What to Expect Once an Order is Placed:

- When ordering our shelters you will receive a full set of CAD drawings for your approval prior to the manufacturing so you can be assured that the shelters are exactly as required.

- Additional onsite training can be requested, to demonstrate the correct inflation, deflation and packing methods to any trainers or end user if required.

- All of our shelters are made to order, allowing us to make any specific changes you may want! Such as adding room dividers or changing window positions upon request!

Technical Information:

- Please see the the Technical Specification tab below

| Heavy-Duty Shelter (Dims) | |

| Shelter (m) | 8m x 6.05m x 3m |

| Inner Chamber | |

| Length (cm) | |

| Int. Length (cm) | |

| Width (cm) | |

| Int. Width (cm) | |

| Height (cm) | |

| Int. Height (cm) | |

| Int. Floor Area (sq.m) | |

| Beam Size (cm) | |

| Air Requirements (ltr) | |

| Working Pressure (ltr) | |

| Packed Size (m) | 1 x 1.8m x 1m x 1m |

| Total Weight (kg) | 280kg |

Contact Us

Need any help? Get in touch with an expert via the contact form below.

What is a Sealed Beam Fast-Inflation Shelter?

The I.C. Brindle Sealed Beam Fast-Inflation Emergency Shelter is a prepacked, rapid-deployment shelter, designed for emergency response and outdoor operations. The beams of the shelter are an airtight welded and glued frame made from heavy duty PVC. On completion, each shelter it is inflated and tested in our test facility for over 72hrs, Our Sealed beam shelters do not need a constant airflow once inflated and are a complete portable solution made to a commercial grade.

What Shelter Sizes are Available?

All our shelters are ‘made to order’ with an approximate lead time of 4 weeks from design to supply. Our most popular size of shelter is a 4m x 5m but we find Fire and Rescue Teams often prefer a smaller 4m x 3m or 3m x 3m unit whilst the military and humanitarian relief organisations prefer larger shelters of around 5m x 8. All shelters come with CAD drawings to support planning and customisation.

-

- Smaller shelters like 3m x 3m, 3m x 4m, and 3m x 2m are commonly used by rapid-response units such as fire services, police, and forensic teams, especially in tight or remote locations. Mid-range sizes like 4m x 5m are suited to medical teams, airport responders, and fire and rescue services.

- Larger shelters such as 5m x 8m are ideal for military field bases, triage centres, and humanitarian relief operations, offering space for extended use or multi-team deployment.

Can I Order a Custom Shelter?

Yes. All of our shelters are made to order so adding custom details like organisations logos, window and door position and size or integrating the shelter into a welfare unit or scientific laboratory isn’t a problem! With all our shelters we will wok with you to create a product that is perfect for its intended use, providing a full set of CAD drawings prior to manufacturing for your approval.

What Sectors or Applications Can Your Shelters Be Used In?

Our shelters are designed to suit a wide range of sectors and applications thanks to their versatile sizes and customizable features. Each shelter size and configuration is suited to specific needs, and we can customise features to fit your exact requirements. Examples include:

- Military operations and tactical deployments

- Medical and emergency triage units

- Fire rescue and incident command posts

- Police and forensic investigation sites

- Search and rescue missions

- Humanitarian aid and disaster relief

- Personnel protection in severe or inclement weather

- Stealth and covert tactical operations

- Mass accommodation and temporary housing

How Quickly Can the Shelter be Inflated and Fully Deployed?

Shelters can be fully deployed in under 5 minutes using an electric pump—no additional frame assembly required. The airtight sealed beam design provides full structural support once inflated. For even faster setup, a 6L, 8L or 12l 300bar BA cylinder can be used, inflating the shelter in as little as 1–2 minutes. ( Shelter inflation times are dependent on the size of the shelter with a 4m x 5m being inflated in 2-3 minutes using a 230v pump).

How Easy is it to Learn How to Unpack and Inflate, Deflate and then Pack the Shelter?

The Sealed Beam Fast-Inflation Shelter is designed for rapid setup in minutes with minimal training needed. Simply roll out the shelter, connect a pump, and inflate using a suitable pump/cylinder, repositioning is easy with grab handles and guy ropes. Packing down is straightforward using the reverse function on the pump—roll, secure, and store in the valise.

Can the Shelter be Used Without Access to Mains Power?

Yes. The shelter can be inflated using a BA cylinder and high presscure hose, or a 12-volt battery-powered pump, making it ideal for remote or off-grid locations where mains power isn’t available, such as a field, or wilderness area. Optional generators can also be supplied for power needs on site.

What Inflation Options are Available?

We offer a variety of inflation and deflation pumps, including:

- 12V Electric Pump

- 110V/230V Pumps

- Automatic pressure regulation pump

- BA Cylinders, 6 litre, 8 litre and 12Litre (For use with a High-Pressure Hose and Regulator)

What Standard Features Come with Every Shelter?

Yes. All custom shelters retain our tried and tested core features as standard. Including our core components:

- Triple-layer window system with fly-mesh, Clear PVC Cover and Privacy Screen

- Large external vehicle flaps for securing the shelter to hard standing

- Safety chevrons at each entrance

- Connectable full-sized doors with smaller inset pedestrian door

- Guy ropes, heavy-duty stakes, and full repair kit

- Clear PVC document pouch at each door

- Carry bag with handles

- Rain gutter system around doorways

- Service ports at each end

- Inflation/Deflation Valves, Overpressure Valve and pressure regulating valve

How Small Can the Shelters be Packed?

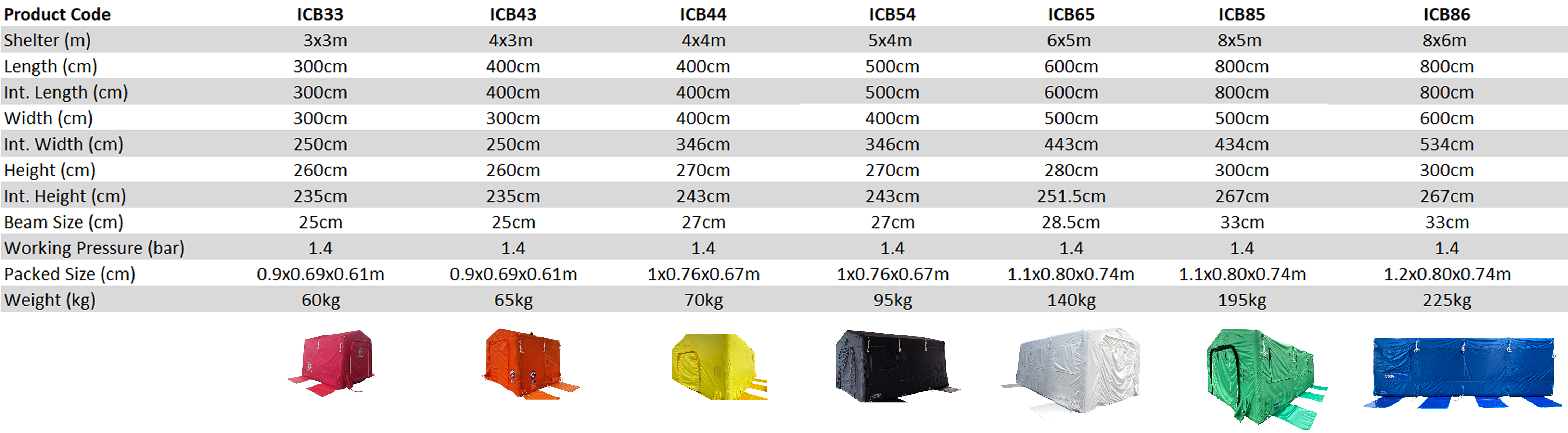

When deflated and rolled, our shelters pack down compactly for efficient storage and transport. Depending on the size and configuration, they are stored in durable bags or protective cases—typically small enough to fit in the back of a vehicle using a easy, two-man lift, or be carried by two people to destination. Typical Packed Sizes are as follows:

Typical Packed Sizes are as Follows:

-

- ICB33 (3x3m Shelter): 90 x 69 x 61 cm, 60kg

- ICB34 (3x4m Shelter): 90 x 69 x 61 cm, 65kg

- ICB44 (4x4m Shelter): 100 x 76 x 67 cm, 70kg

- ICB45 (4x5m Shelter): 100 x 76 x 67 cm, 95kg

- ICB56 (5x6m Shelter): 110 x 80 x 74 cm, 140kg

- ICB58 (5x8m Shelter): 110 x 80 x 74 cm, 195kg

- ICB68 (6x8m Shelter): 120 x 80 x 74 cm, 225kg

Are the Shelters Flame Retardant?

All of our shelters use the latest PU coated Nylon material, which is manufactured within Europe. This material is not only lighter than heavy canvas shelters which industries are now moving away from but it is also waterproof, water resistance and flame retardant. Features such as vehicle flaps for securing on hard standing and upper and lower guy ropes provide stability on softer ground.

Can the Shelter Withstand Strong Weather?

Yes. The sealed beam design, with offset and reinforced beam joints, combined with the flame retardant canopy materials, gives your shelter excellent stability and resistance to wind, heavy rain, and temperature changes. Standard features such as guy ropes and vehicle flaps secure anchoring in challenging environments and ensure that your shelter stays strong against the elements, such as heavy wind and rain. This makes the shelter ideal for use in situations such as firefighting operations, disaster relief zones, military field bases, and remote medical setups.

How Does the Shelter Handle Pressure Changes from Temperature

The shelters are inflated ‘in house’ for a period of 72 hours before despatching, if the shelters are being used for longer terms the pressure regulating valve, which is fitted as standard, can be utilised with a pressure sensor pump, the pressure sensor pump can be set at the mbar required and will automatically regulate the pressure if the mbar falls below the pressure set.

Are the Shelters Connectable?

Yes, our shelters feature a modular design with full-sized zippered connectable doors. This allows you to join multiple units easily, creating larger operational spaces or separate zones tailored to your specific needs. The modular setup lets you be flexiable with your shelter layout.

How Easily Can the Shelters be Moved Once Set Up?

Our shelters can be moved and repositioned easily because they are lightweight and built as a single-piece unit. The shelter’s outer canopy is securely fixed to the sealed beam frame with strong Velcro. Grab handles at the corners and along the base allow quick repositioning without deflation—ideal for rapid deployment and fast-moving situations.

How are Lighting and Heating Integrated into the Shelter?

The shelter includes internal ‘D’ rings on the beams for attaching lighting, heaters, or room dividers. Service ports at either end allow for safe, sealed entry of power cables, ducting, or heating hoses. Optional accessories like internal lighting kits, heaters, and generators can be supplied as part of a fully configured package—ready to deploy out of the box for your shelter.

Do you Provide Drawings Prior Manufacturing?

Yes. All confirmed orders receive a set of CAD drawings prior to the manufacturing process for your approval, this ensures that we will be manufacturing, and you will be receiving the exact solution you require.

What is the Lead Time for a Standard and Customised Shelter?

From start to finish you can expect your shelter to take approximately 4 weeks to despatch from the design approval