I.C. Brindle's SOLAS & Marine Tape Buyer's Guide: What Tape Should I be Using?

Introduction

Welcome to our buyer's guide for SOLAS & Marine Tapes – your go-to resource for understanding the purposes of these unique safety and protection tapes, and learning how to use them correctly. SOLAS tapes are designed to solve specific problems and enhance safety measures. In this guide, we'll delve into the key purposes of SOLAS tapes and provide insights into their correct usage.

- SOLAS tapes, also known as Safety of Life at Sea tapes, are specialised adhesive tapes designed to enhance visibility and safety in marine environments. These tapes are formulated with high-performance safety technology, such as retro-reflective material, which ensures light is reflected back to its source, making them highly visible even in low light conditions. SOLAS tapes are primarily used on vessels, life-saving equipment, and offshore structures to improve visibility and prevent accidents.

- General Marine Safety Tapes, offering versatile solutions for maritime environments. Gain practical insights into their applications and their crucial role in enhancing safety across marine settings and workplaces.

SOLAS Tape Categories

Understanding the multitude of tape options and selecting the most suitable one for particular scenarios can indeed be overwhelming. In this selected guide, we aim to simplify this process by offering insightful explanations about the distinct roles each chosen tape fulfills. Exploring a diverse range of SOLAS tape varieties listed on our website, analysing their designs, intended purposes, and application methods. By delving into these safety tapes comprehensively, you'll be well-equipped to employ them effectively as needed.

These SOLAS tapes can be conveniently categorised as follows:

- Anti-Leak and Splashing Tapes (Spray Stop, Spray Control)

- Insulation Tapes (Drip Stop)

- Reflective and Marking Tapes (Retro-Reflective, Floor Marking, Light-line Photoluminescent)

- Additional and Miscellaneous Tapes (Hatch Cover Blueliner, Slip Stop / Anti-Slip)

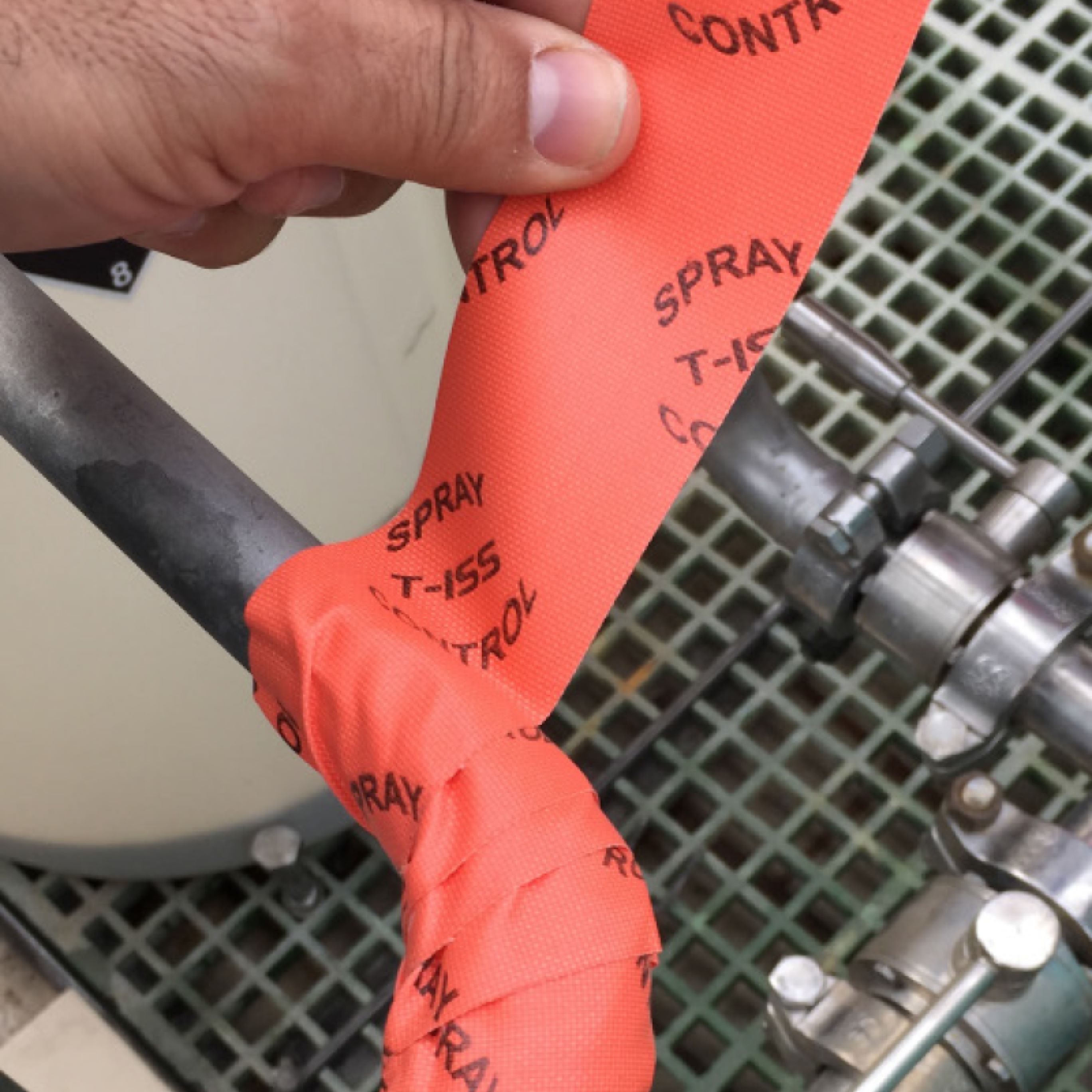

Spray Control Tape: Enhancing Chemical Plant Safety Against Spray-Outs

What Spray Control Tape?

Spray Control Tape, a powerful solution designed to safeguard chemical installations from spray-outs effectively. Unlike Spray Stop Tape, this unique product offers distinct advantages tailored to enhancing safety within pipeline systems on chemical plants. By implementing Spray Control, you can significantly elevate your safety protocols to align with stringent chemical industry standards.

Specially engineered to mitigate risks, Spray Control Tapes act as a robust barrier, preventing potential harm to personnel, machinery, and surrounding pipes in the vicinity. This versatile tape is optimized to provide unparalleled protection to chemical tubing systems operating within the temperature range of -30 °C to 75 °C. Furthermore, it boasts impressive resilience, capable of handling pressures of up to 35 bar.

Upgrade your chemical plant's safety measures with Spray Control Tape, ensuring comprehensive protection against spray-outs, even in demanding environments. Trust in this advanced solution to fortify safety and maintain optimal operations.

When to Apply Spray Control Tape:

When seeking reliable protection for tubing systems within chemical installations, consider the exceptional benefits of Spray Control Tape. This innovative solution effectively safeguards against accidents and leakages, mitigating potential hazards and ensuring the well-being of personnel in the vicinity. Spray Control Tapes are the ideal choice for tubing systems operating within the temperature range of -30 °C to 75 °C. Elevate safety and prevent mishaps with Spray Control Tape today.

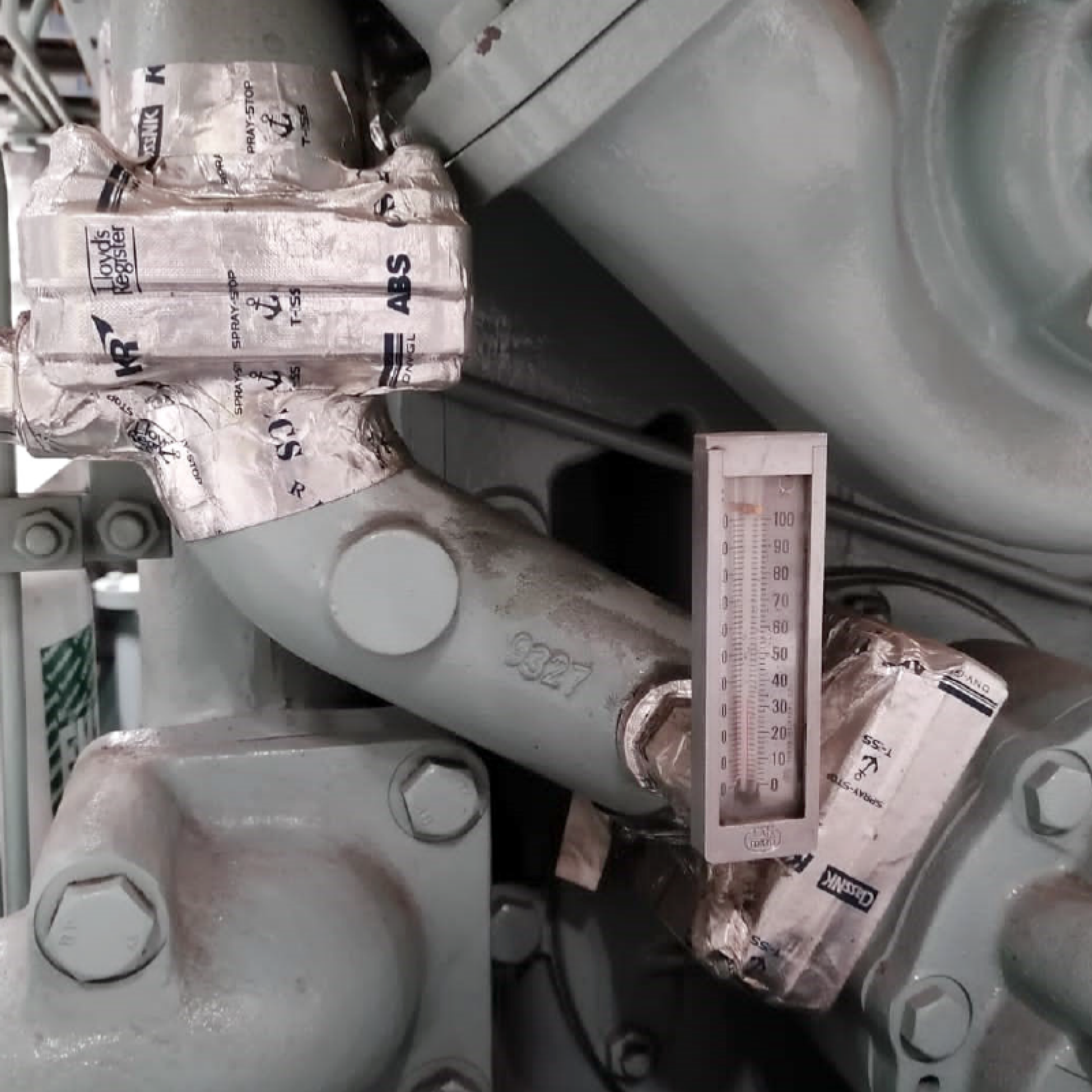

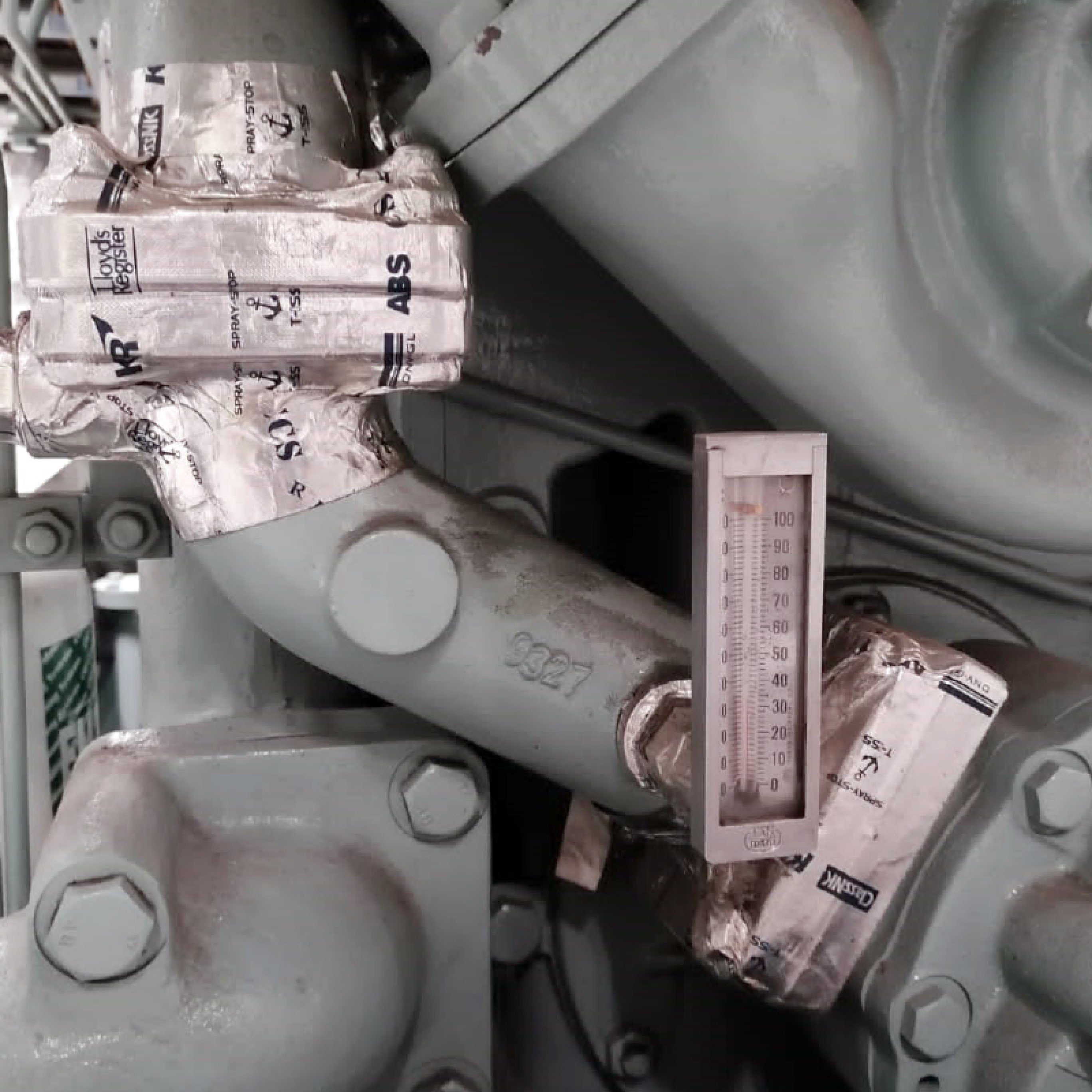

Spray Stop Anti-Splashing Tape: Marine & Offshore Protection Solution

What is Spray Stop Tape?

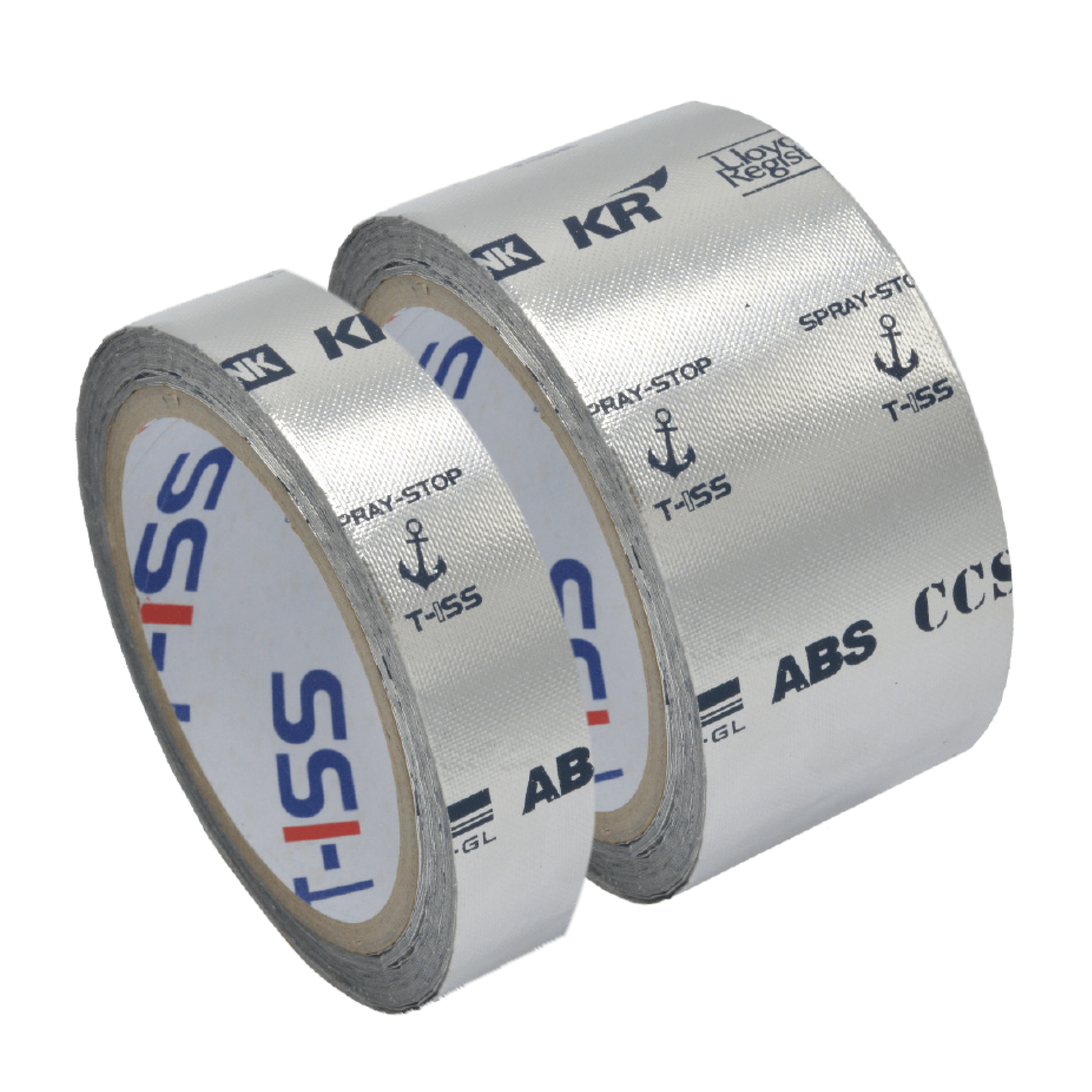

Engineered by safety specialists for marine and offshore applications, Spray Stop Anti-Splashing Tape stands as a cutting-edge, laminated multilayer aluminum solution. Tailored to counteract hazardous liquid spray-outs—such as oil and fuel—from tubing systems, this innovation effectively averts potential fire, explosion, and perilous situations.

Mandated by SOLAS regulations, ships must adopt measures to curtail leakage and splashing of flammable oil, ensuring compliance and safeguarding the environment. Spray Stop Tape emerges as a reliable answer, upholding regulations and guaranteeing worker well-being.

Its resilient construction is engineered to endure the unforgiving marine environment, making Spray Stop Anti-Splashing Tapes are indispensable for averting accidents and spills in high-risk industries. By applying this tape, tubing systems within the marine and offshore sectors can be transformed into safer environments, reducing the risk of injuries, equipment damage, and environmental harm.

When to Apply Spray Stop Anti-Splashing Tape:

In the context of offshore drilling for example, tubing systems carrying hazardous liquids like oil and fuel would be prominent. To help avert potential disasters, the Spray Stop Anti-Splashing Tape offer a vital solution. Made by safety specialists, this high-tech laminated multilayer aluminum tape forms a resilient barrier against spray-outs from tubing systems. The safety tape provides a proactive measure that curtails the risk of fires, explosions, and dangerous situations caused by such spray-outs. In compliance with SOLAS regulations, this tape offers crucial protection, preventing leakage and splashing of flammable oil, ensuring the safety of both personnel and the marine environment.

DripStop Tape: An All-Rounder Insultation Solution

What is Drip Stop Tape?

Drip Stop Tape stands as a remarkably adaptable product with a multitude of applications, making it an all-encompassing solution. Its compact nature eliminates the need for additional tools, making installation a seamless process – the tape adheres to itself, ensuring a mess-free experience.

This versatility shines through in its functions; the Drip Stop Tapes excel in protecting against leaks and splashes, sealing tubing with air or powders, and acting as a barrier against corrosion, salts, water, and weather conditions. Furthermore, it finds utility in safeguarding and insulating cables, offering invaluable support for a range of daily maintenance tasks.

When to Apply Drip Stop Tape:

Drip Stop Insulation Tape offers a hassle-free approach, devoid of adhesive components, ensuring effortless handling. Its unique adhesive-free design allows it to adhere to components, making it applicable on wet surfaces and even pressurized leaking piping (up to 3 kg/cm²), including underwater usage. The insulation tape's versatility extends to serving as a shield against corrosion and providing electrical insulation. Boasting a swift cure time of around 20-30 minutes, it swiftly delivers efficient solutions.

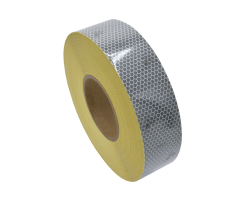

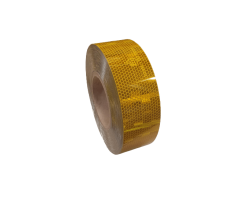

Retro-Reflective Tape: Enhancing Visibility in Low-Light and Night Environments

What is Retro-Reflective SOLAS Tape?

SOLAS Retro-Reflective Tape, also known as 'SolaxFlex' tape utilises encapsulated lens sheeting for reflective purposes. This lens design maximizes reflectivity across diverse angles, in both wet and dry conditions. With a flexible and transparent film, this reflective tape achieves exceptional brightness—ranking among the highest intensities in the market. Noted for its prolonged durability, intense brightness, and anti-delamination properties.

Adhering to IMO Res. A658(16) and in alignment with USCG specification 46 CFR Part 164, this product bears approvals including wheelmark, USCG, RR, and KR. T-ISS SolasFlex holds a Type 2 approval, rendering it versatile for both indoor and outdoor applications. Classified as a Type 2 solasgrade tape, SolasFlex Tapes are apt for sustained outdoor usage.

How to Apply Retro Reflective SOLAS Tape:

this retro-reflective tape finds its primary application in enhancing the visibility of SOLAS life support equipment. This includes vital items like life vests, lifebouys, life boats, and life rafts. The incorporation of Retro-reflective tape ensures these pieces of equipment remain highly visible, particularly when helicopter lights are employed in search operations. The versatility of this product shines as it can be both pasted and stitched onto various surfaces, amplifying its range of potential applications.

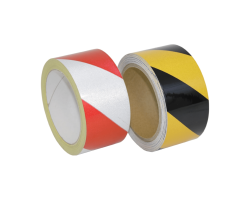

Reflective Safety Marking Tape: Providing Safety & Preventing hazards

What is Reflective Safety Marking Tape?

Safety Marking Reflective Tape—an exceptional product designed for optimal safety and protection. This Reflective Safety Tape has a reflectivity level 200 times that of a white wall, this tape delivers remarkable visibility. Complemented by distinctive zebra colour patterns such as red and white or black and yellow, it becomes a notable choice. Its effectiveness in preventing hazards and accidents makes it a valuable addition. If a photoluminescent option with a similiar function is of interest, LightLine Tape would be the go-to choice for your safety marking needs in low-light conditions.

When to Apply Safety Marking Tapes:

Safety Marking Photo-luminenscent Tape offers exceptional safety and visibility benefits. Made from enclosed lens retroreflective material, it effectively accentuates hazards and danger zones in low-light or dark scenarios. With over 200 times greater reflectivity than white paint, it significantly elevates safety across various settings. Particularly suited for vessels, it ensures round-the-clock protection. Whether it involves marking hazardous areas or enhancing visibility, Reflective Safety Marking Tapes serve as a dependable and enduring solution to bolster your vessel's daily safety protocols.

Light Line Tape: Total Compliance with IMO & SOLAS Regulations

What is Lightline Tape?

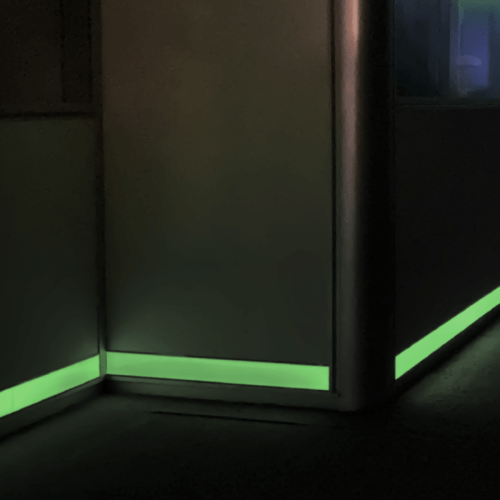

Made from a blend of PVC, PU, and PET materials, our photoluminescent tapes offer resilience against weather and are fitting for both indoor and outdoor applications. Notably, PU material excels in heavy-duty scenarios and on curved surfaces. With outstanding visibility and safety, even in low-light situations, these glow-in-the-dark tapes are an optimal choice for marking exits, pathways, and identifying hazards — compliant with IMO and SOLAS regulations.

When to Apply Photo-Luminescent Light Line Tapes:

the application of top-quality photoluminescent tapes becomes a safety imperative. Made from PVC, PU, and PET materials, these tapes excel indoors and outdoors, providing exceptional weather resistance for various applications. For example, envision a ship's corridors and stairwells, frequented by passengers and crucial during emergencies. These reflective photo-luminescent tapes would ensure clear visibility, guiding passengers safely, even in low-light conditions. Their strong adhesive layer and adherence to stringent safety standards assure both crew and passengers of their effectiveness. As power outages or dimly lit situations arise, the luminescent properties of these glowing in the dark tapes prove indispensable, enhancing safety protocols across the ship.

Hatch Cover Tape: Enabling Weather-Tight Seals for Leakage Protection

What is Blueliner Hatch Cover Tape?

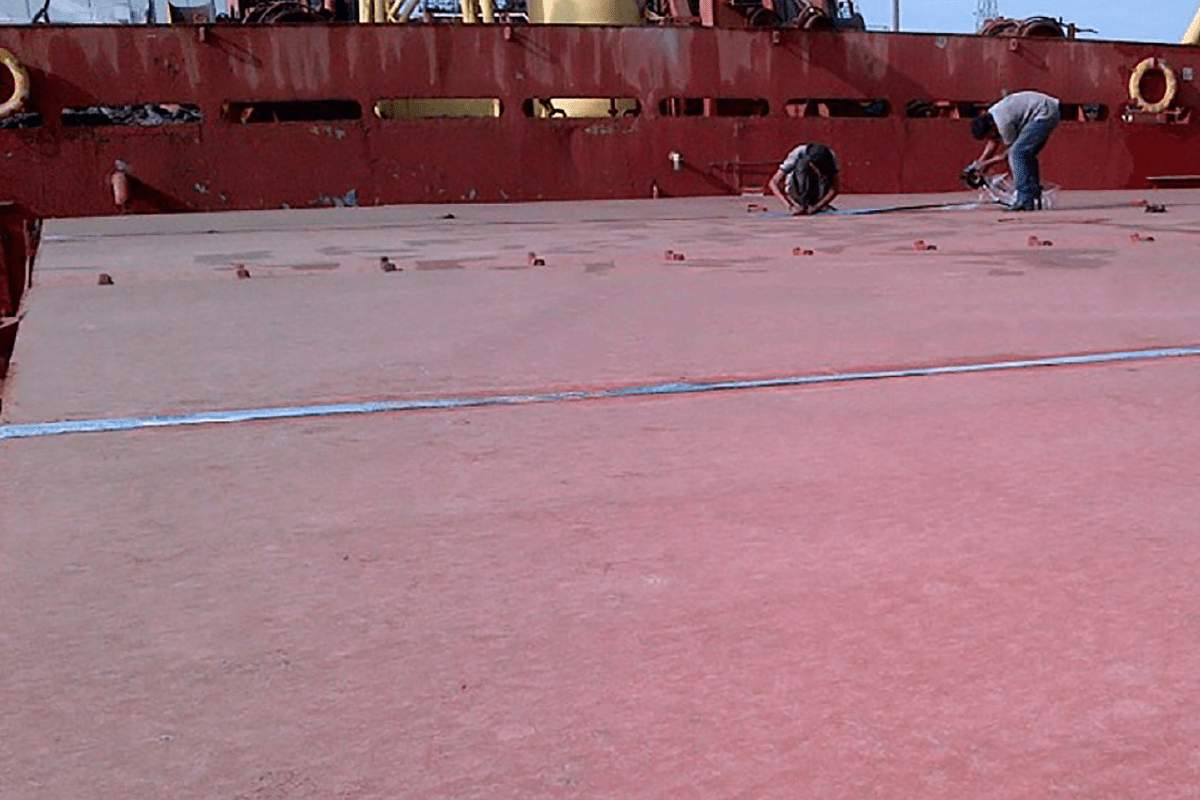

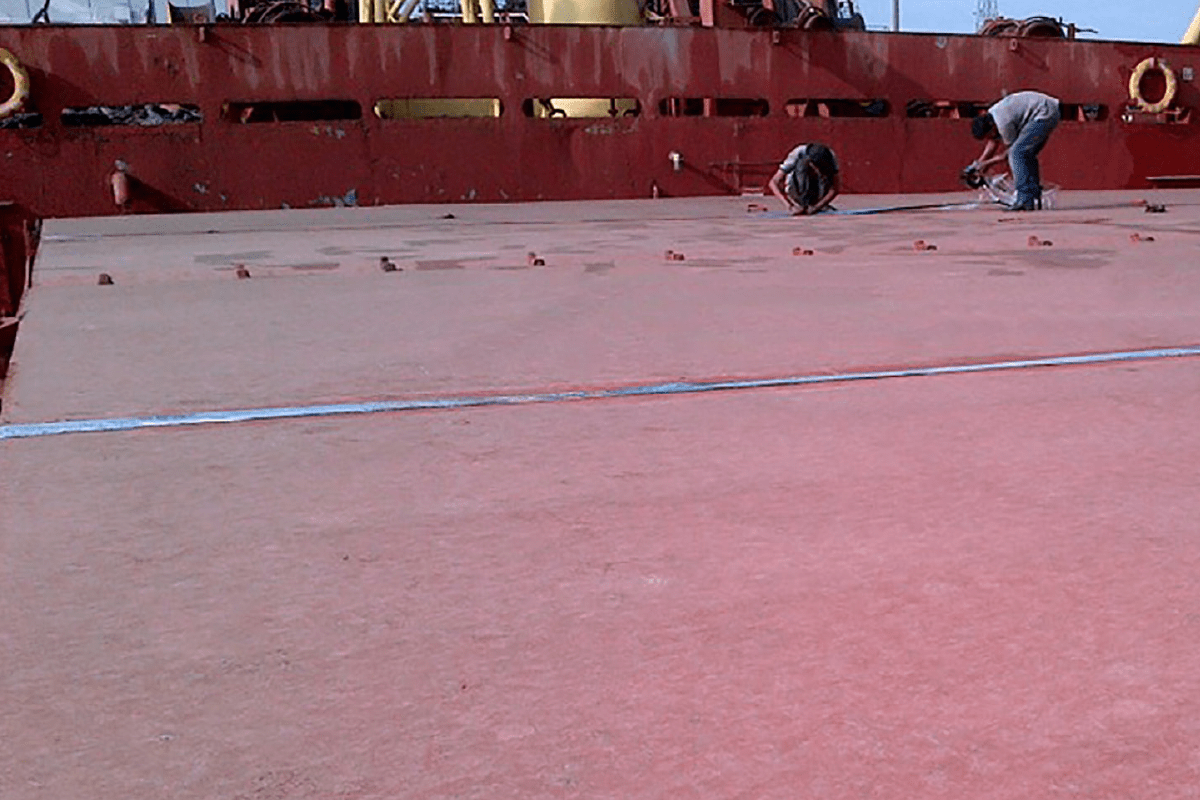

Hatch Cover Blueliner Tape is a highly durable solution designed for extreme weather conditions, offering reliable performance. With a temperature range of 5°C to 40°C, it boasts exceptional flexibility and endurance, enduring temperatures from -15°C to 70°C. Each roll contains 20 meters of self-adhesive SBS bitumen rubber compound for strong adhesion and sealing. The hatch cover tape features a modified blue PE liner and release PE liner for user convenience. It forms a tight protective seal, ensuring cargo safety during transport in varying weather conditions. This 2mm-thick self-adhesive solution, coated with modified blue PE and release PE liners, remains effective between -15°C to 40°C temperatures. Properly stored, it maintains quality for up to 5 years.

When to Apply Hatch Cover Blueliner Tapes:

During harsh weather, cargo vessels' hatch covers can face leakage, potentially damaging transported goods. To counter this, Hatch Cover Blueliner Tape provides a robust solution. It wards off moisture, ensuring a secure, weatherproof, and smoke-resistant seal. The tape excels in strength, adhesion, and flexibility, featuring a distinctive blue top layer of modified PE material that offers superior protection during extreme conditions.

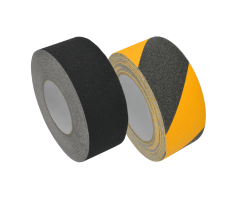

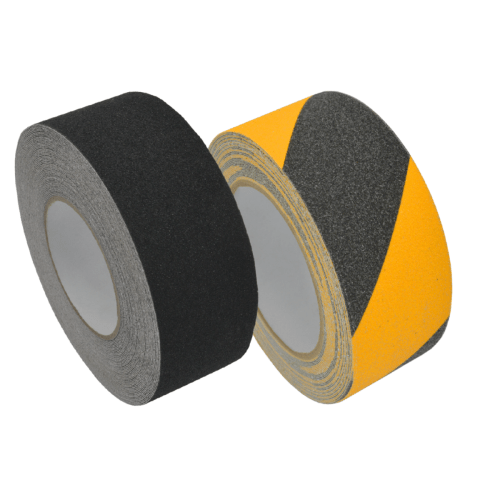

Anti-Slip SlipStop Tape

What is SlipStop Anti-Slip Tape?

Anti-Slip Tape is an essential solution for creating safe environments. With exceptional slip resistance, it features a mineral-coated plastic film and pressure-sensitive adhesive for durability. Suitable for indoor and outdoor use, its versatility extends year-round within a temperature range of 5°C to 50°C. The high-visibility design enhances safety awareness, while easy installation and removal offer a cost-effective, low-maintenance choice. Backed by reliable performance, it assures user confidence. Technical specs include a 0.8 mm tape with 1 - 0.2 mm grit thickness, 1500 g / 25 mm steel adhesion, 6 kg / 25 mm tensile strength, and application between 5°C to 50°C.

When to Apply Anti-Slip Tapes:

Combining a mineral-coated plastic film, pressure-sensitive adhesive, and aluminum oxide mineral particles, it stands as a potent solution for superior slip resistance. Whether indoors or outdoors, this versatile grip tape's application spans a temperature range from 5°C to 50°C. For instance, when addressing safety concerns in a busy stairwell aboard a vessel with flooring prone to becoming slick, applying Anti-Slip Tape to key walkways and staircases would provide a reliable safeguard, ensuring secure and hazard-free passage for employees and visitors alike.

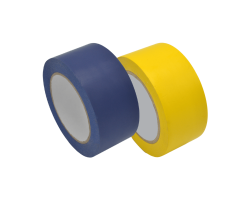

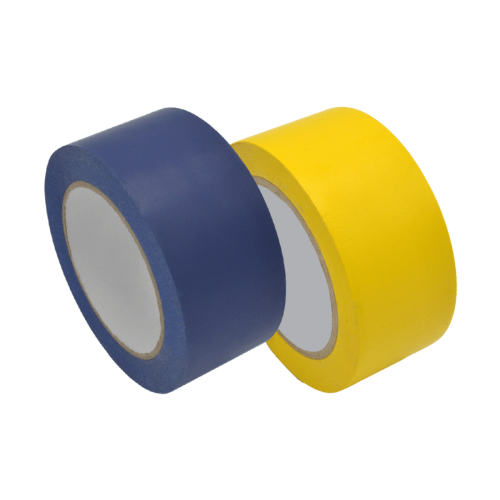

Floor Marking Tape: Marking Walways and Promoting Workplace Safety

What is Floor Marking Tape?

Floor Marking Tape is designed for safety enhancement in workplaces and public areas by marking floors and walkways. It boasts durability through high-quality adhesive, making it suitable for tough environments. This tape serves to designate hazardous areas, promoting safety and accident prevention. Whether for traffic lanes, fire exits, or workplace hazard warnings, it offers versatile application. Resistant to foot traffic, abrasion, moisture, and extreme temperatures, it adapts to various uses. Available in diverse colors and sizes, customisation is feasible, while easy installation and removal add practicality.

When to Apply Floor Marking Safety Tapes:

Within a maritime working environment on a cargo vessel, safety is paramount. By utilising Floor Marking Tapes, you can significantly enhance safety protocols. For instance, on the ship's deck, using this tape to mark designated pathways for crew movement can prevent accidents. The Blue Floor Marking Safety Tape could clearly indicate safe walkways, while the red tape could highlight areas with potential hazards. Moreover, applying the tape near equipment or hatches with extreme temperature exposure, such as engine rooms, ensures longevity due to its resistance to temperature variations. In this maritime context, the Floor Marking Tape plays a vital role in guiding safe navigation and highlighting danger zones, contributing to an overall safer working environment for the crew.

Marine Safety Foam Tape: An All-Round Weather-Resistant Double-Sided Adhesive Tape

What is Foam Mounting Tape?

Foam Mounting Tape is more than just adhesive; it's among the toughest tapes available, supporting up to 1.8 kg / 25 mm for permanent object attachment. With impressive chemical resistance, it excels in outdoor and harsh weather settings. Featuring a protective layer, you can apply it to objects and attach them to surfaces later. Basically, Foam Mounting Tape is more than just adhesive; it's among the toughest tapes on the market!

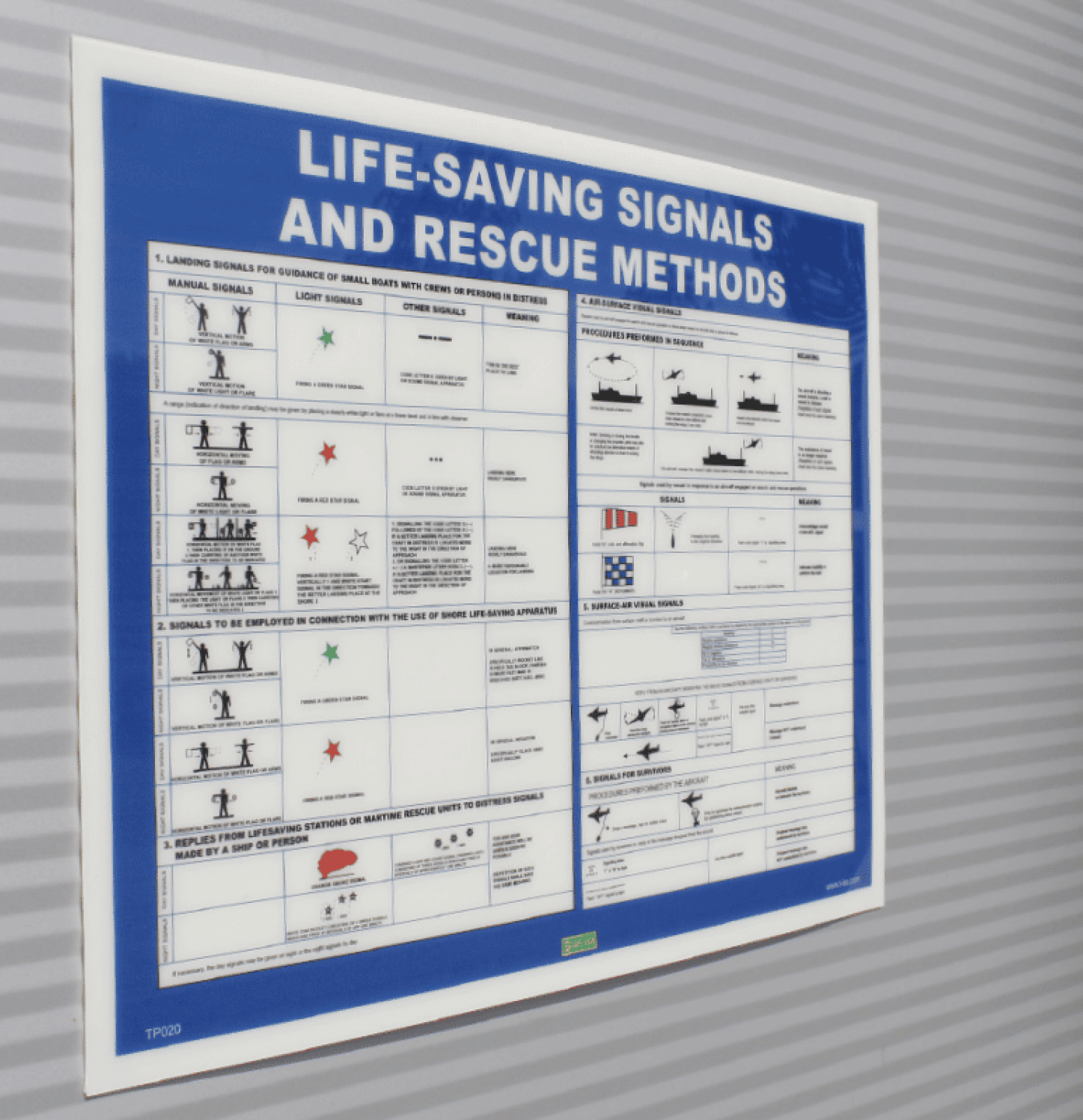

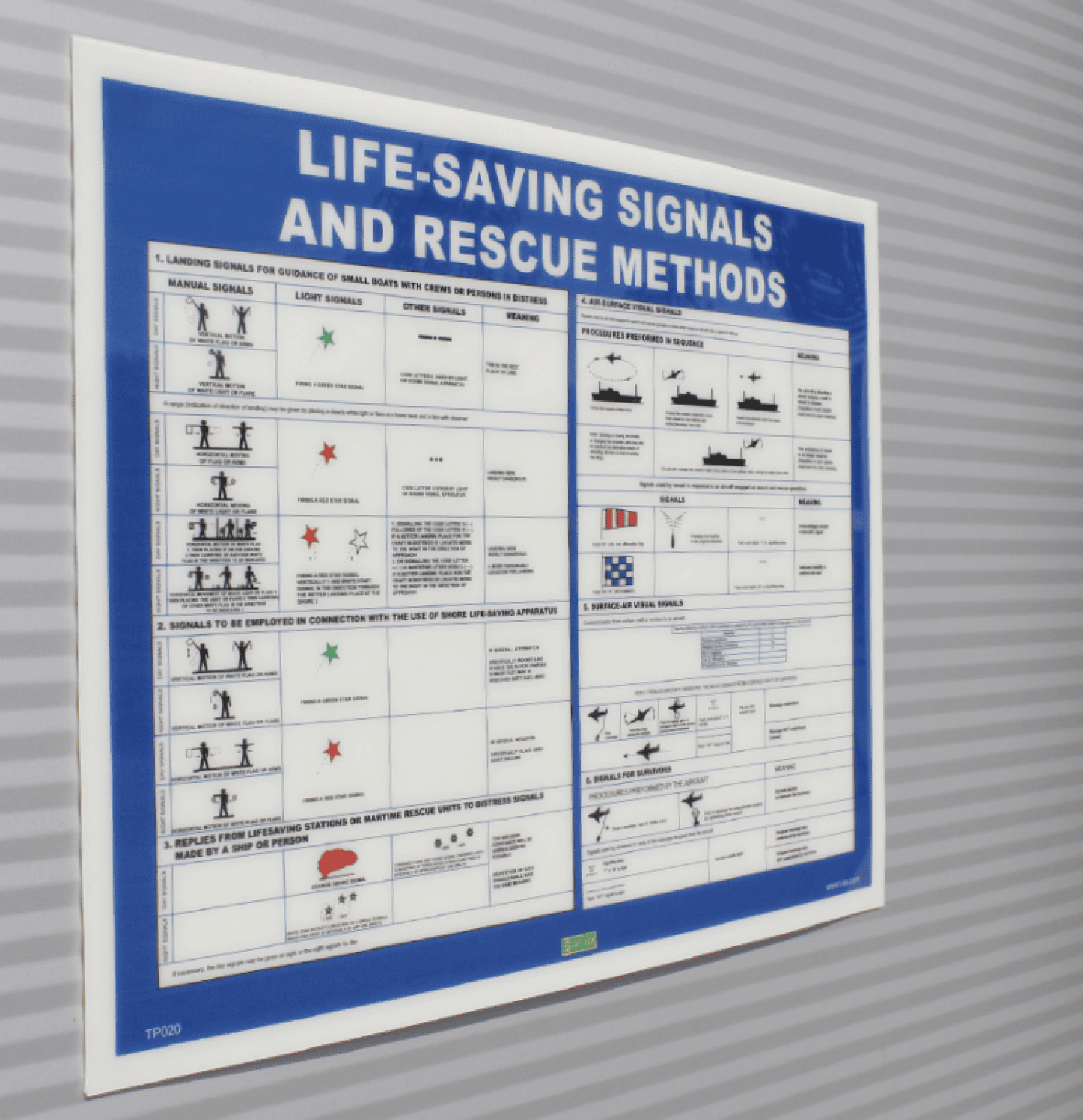

How to Apply Foam Mounting Tape:

When it comes to permanently fixing objects like signs, nameplates, trims, and emblems to surfaces, Foam Mounting Tape is the optimal choice. Additionally, you have the option to apply a Foam Mounting Tape backing to a product for later use, providing a future-use option when necessary. This marine safety tape is well-suited for mounting safety signs on vessels, including ferries and transport ships.

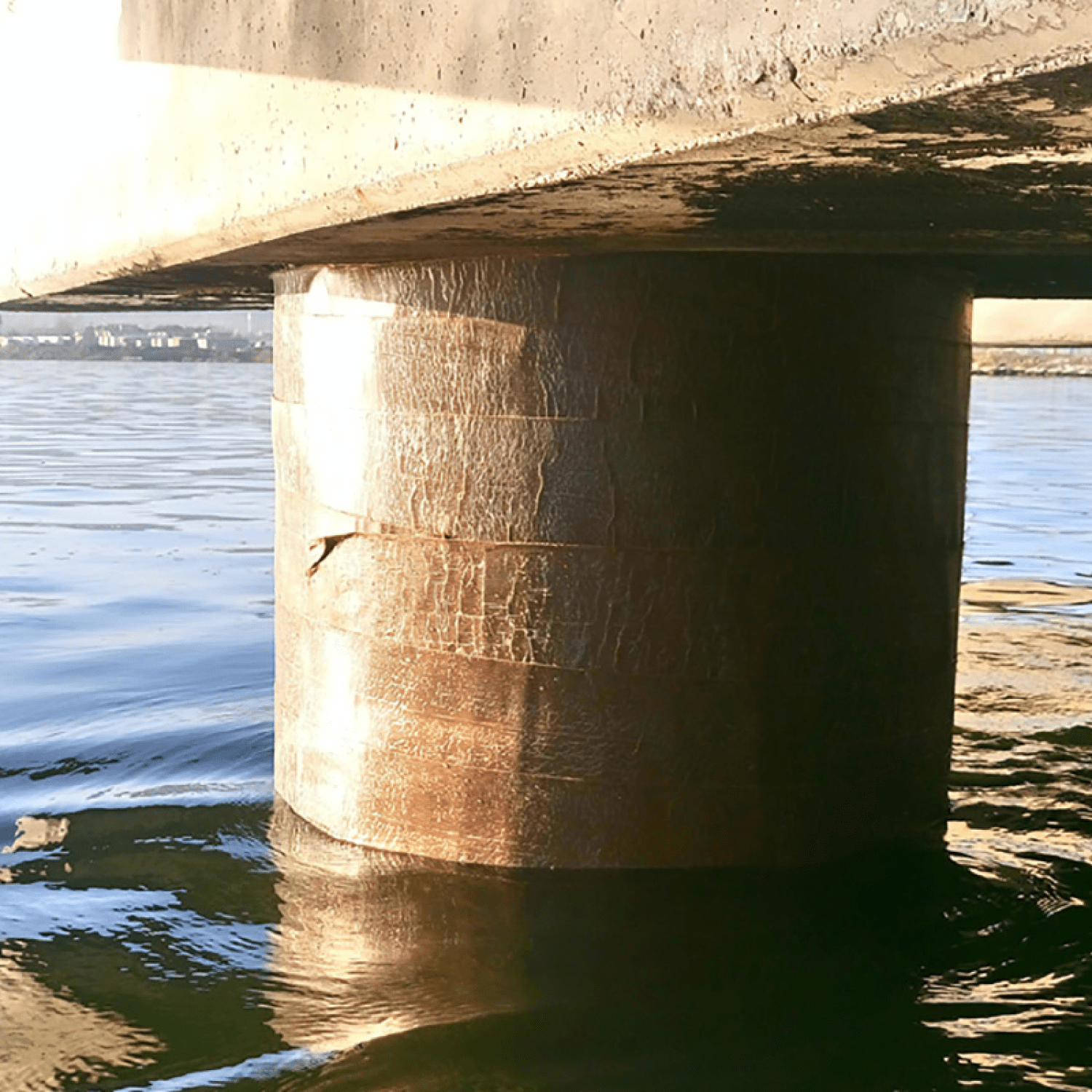

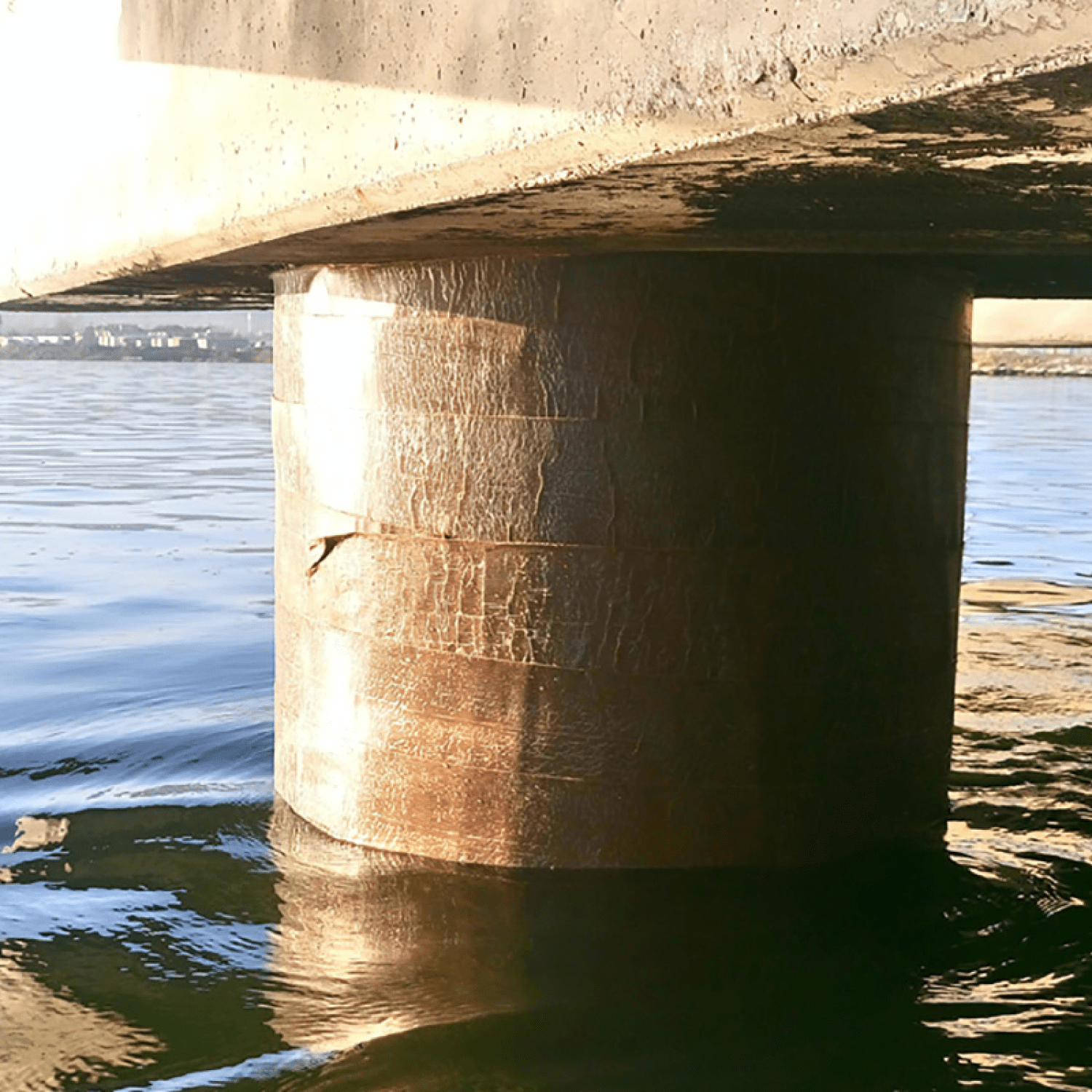

'CorStop Anti-Corrosion Zinc Tape: Your Reliable Defence Against Marine Galvanic Corrosion

What is CorStop Corrosion Stop Zinc Tape?

Engineered for steel components like bridge supports and pipelines, this high-purity zinc tape boasts a durable self-adhesive backing. By sacrificing itself, it shields linked metals from galvanic corrosion, bolstering rust protection and enhancing marine safety. This principle also applies to ships' hulls through anodes. Here's the concept: when diverse metals, such as tubing systems, connect, rust can form. This tape redirects rust to itself, safeguarding the metals. Similarly, anodes on ships' hulls rust instead, ensuring prolonged rust-free hulls.

When to Apply Anti-Corrosion Tape:

First of all, you could use Corrosion Stop Zinc tape when fixing steel structures together. When you apply Corrosion Stop Zinc tape in these situations, you will prevent galvanic corrosion and your materials will last a lot longer. Also, the fluids or goods that are transported in, for example, tubing systems, will not be exposed to corrosion. This way, the corrosion will not affect the transported product. A 'self-sacrificing' marine safety product like Corrosion Stop Zinc tape could also be used in other cases; for example as a sacrficial anode on a ship’s hull!

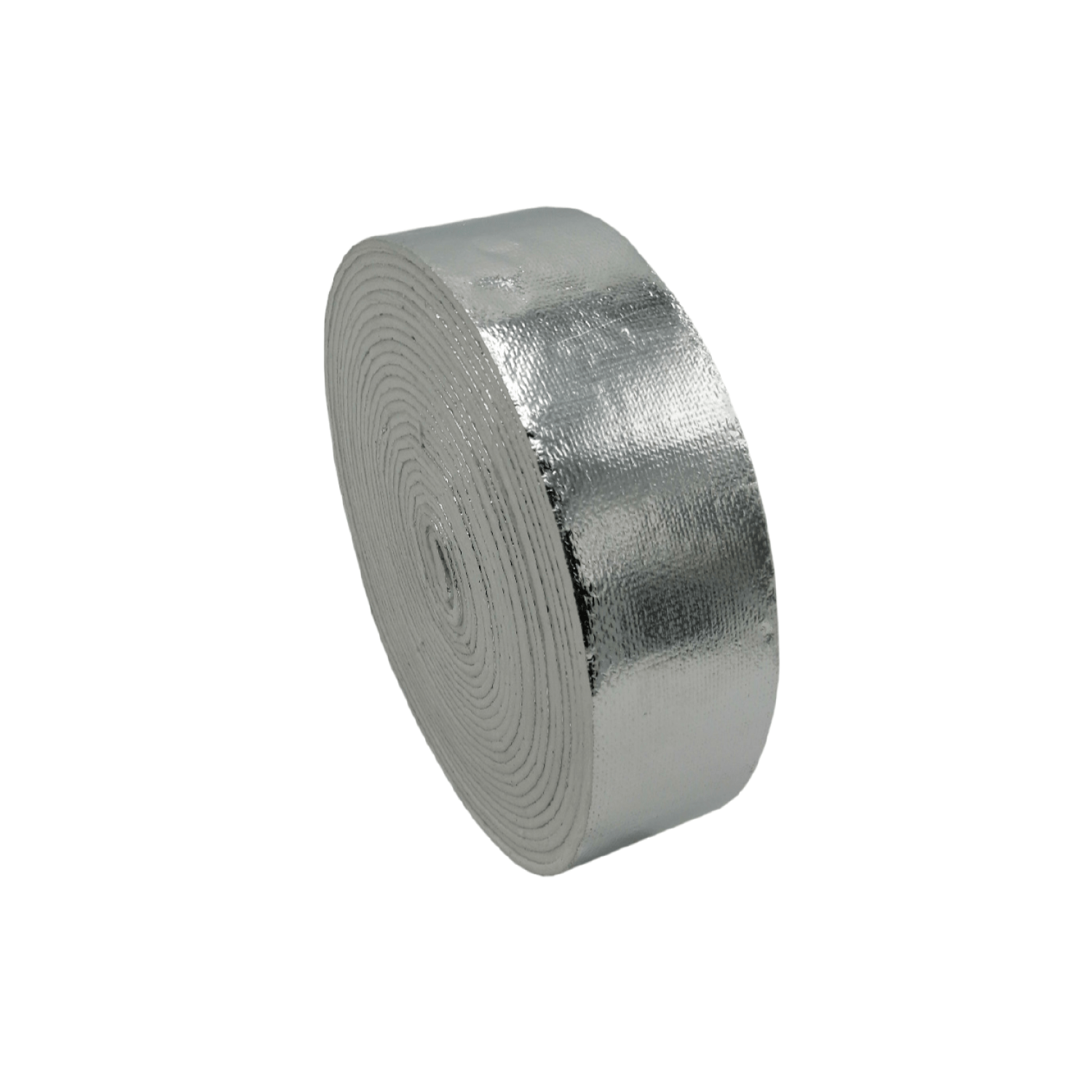

'RustStop' Petro Tape: Your Advanced Rust Prevention Solution for Tubing Systems and Structures.

What is RustStop Petro Tape?

An innovative marine safety tape that is leading the way on rust prevention for tubing systems and structures. Designed with a specially designed weather-resistant bandage material, infused with a curated rust-resistant blend of oil and grease that shields sensitive materials from rust. Alongside this, the oil and grease mixture halts oxidation, providing enduring protection, even underwater.

When to Apply Rust-Resistant Tape:

Created to protect steel structures, Rust Stop Petro Tape sticks easily to different surfaces, fending off water, acids, alkalis, and salts. It works underwater and in tough weather, staying strong without peeling or cracking. Applying it is easy, and the tape is solvent-free. It's 1.2mm thick for solid protection. For example, imagine a steel beam supporting a vital section of a ship's deck. Over time, exposure to seawater and salty air may lead to rust, compromising the beam's integrity. Applying Rust Stop Petro Tape to the steel beam will create a protective barrier, shielding it from corrosive elements and ensuring the structure remains robust and durable within the harsh marine enviroment.

'HeatStop' Biosoluble Heat Stop Tape: Effectively Safeguards Surfaces while reducing temperatures

What is Biosoluble Heat Stop Tape?

This thermal insulation tape not only shields surfaces but also reduces temperatures significantly. It cools a 180°C tube to just 60°C, surpassing competitors at 95°C. Made from advanced biosoluble fibers, it outperforms traditional ceramic fiber tape in both performance and sustainability. With a unique chemical composition, it excels in durability and biodegradability. Woven with stainless steel wires and fiberglass filament, it maintains high-temperature performance. Compliant with BV regulations, ensuring maritime safety standards. Perfect for temperature reduction in maritime and offshore settings, offering efficient and environmentally responsible cooling.

When to Apply Biosoluble Heat Stop Tape:

In the maritime and offshore sectors, achieving temperature reduction is often crucial. Heat Stop Soluble Tape achieves this significantly, effectively lowering temperatures in tubing systems while being environmentally friendly. It's an advanced, safe, and highly efficient solution that prioritizes both performance and eco-friendliness, ensuring no harm to your health.

Conclusion:

This SOLAS Tape Buyer's Guide serves as an invaluable resource for individuals seeking the right tape solutions within the maritime domain. Navigating through the various options, from reflective marking tapes to corrosion prevention tapes and many more. Offeing you a comprehensive understanding of each product's attributes and applications. With insights into specialised SOLAS tapes designed for enhanced visibility and compliance, as well as versatile marine safety tapes, the guide empowers the reader to make informed choices for their specific needs. Whether it's optimising safety, corrosion prevention, or marking efficiency, this guide equips you with the knowledge needed to select the ideal tape solution — ensuring maritime operations meet the highest standards of quality and safety. .